Helium Leak Testing - Automotive Components

HELIUM LEAK TESTING

( Fuel Tanks)

Fuel tanks have previously been regarded as leak testing problem. The volume is unstable and too large for Air decay testing. Water dunk method is operator dependent , unreliable and causes long term damage to the unpainted tank. Neither method could detect a fine vapor leak.

PIS is able to supply Fuel tank leak testing using Helium. The system provides a fast reliable dry test with numerical leak results. The sensitivity is better than "Water Dunk bubble" test method. Automatic Quick sealing fixtures, Self monitoring systems enables unskilled operator to be deployed.

The system is suitable for leak testing metal or plastic tanks.

Technical Specifications

-

Leak Detection Rate : 1 x 10 E -4 mbarl/s

-

Cycle Time : 30 to 60 Secs

-

Calibration routine : Automatic

-

Background suppression : Auto Zero

-

Helium Mixing ratio : 1 to 100%

-

Helium Recovery : > 95%

HELIUM LEAK TESTING

( Refrigerant Components)

Phoenix Industry solutions ( PIS ) offers reliable Helium Leak Testing Machine which is used to Test the Automotive refrigerant parts with volume ranging from 0.001 m3 to 0.1 m3using Helium gas at pressure ranging from 30 PSIG to 3000 PSIG.

It is specially designed for Vacuum based Helium leak test applications, such as Refrigeration components, pipes and manifolds etc. It comes with optional Recovery System HHRS to recycle the expensive Helium Gas for the Leak Testing

APPLICATION

Leak Testing of Auto components- Heat Exchangers, Evaporators, Condensers , Radiators, EGRs etc

Technical Specifications

-

Leak Detection Rate : 2 x 10 E -5 mbarl/s

-

Cycle Time : 1 min

-

Calibration routine : Automatic

-

Background suppression : Auto Zero

-

Helium Mixing ratio : 1 to 100%

-

Helium Recovery : > 95%

Ac pipes , Hosses and Tubes assemblies requires integrated Leak testing to ensure leak tightness in application of Automotive refrigerant lines. Helium leak testing machine developed for leak testing posses a inherent challenges owing to permeability of rubber hosses in the assembly. Carefully designed machine can overcome the challenge for successful leak testing.

Key Highlights are : Multiple Parts checking, Quick Changeover fixtures to accommodate different varieties of AC pipe assemblies and reduced cycle time for higher productivity.

Technical Specifications

-

Leak Detection Rate : 2 x 10 E -5 mbarl/s

-

Cycle Time : 60 secs

-

Calibration routine : Automatic

-

Background suppression : Auto Zero

-

Helium Mixing ratio : 1 to 100%

-

Helium Recovery : > 95%

HELIUM LEAK TESTING

( Alloy Wheels)

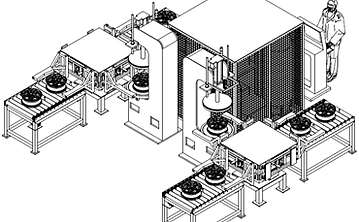

We have specially developed Helium Leak Testing machine to test Alloy Wheels ( Passenger Cars ), with high accuracy, low helium consumption and quick cycle time. The leak testing machine can be independent equipment OR integrated with Automatic production line.

Technical Specifications

-

Leak Detection Rate : 1 x 10 E -4 mbarl/s

-

Cycle Time : 10 Secs

-

Calibration routine : Automatic

-

Background suppression : Auto Zero

-

Helium Mixing ratio : 5%

-

Helium Recovery : > 95%

HELIUM LEAK TESTING

( CNG Components - 300 bar )

Helium Leak Testing application for CNG components such as HP Regulators in Automotive requires Leak testing not only at high pressure ( 300 bar ) but also during operation with coil operated inside the chamber. Internal , External and whole body leak testing is performed during the Auto cycle check. Other parts such as Receptacle, HP Tubes etc are also tested with helium Leak testing method.

Technical Specifications

-

Leak Detection Rate : 1 x 10 E -4 mbarl/s

-

Cycle Time : 60 Secs

-

Leak Testing Pressure : 300 bar

-

Calibration routine : Automatic

-

Background suppression : Auto Zero

-

Helium Mixing ratio : 5%

-

Helium Recovery : > 95%

HELIUM LEAK TESTING

( Hydrogen Components - 1000 bar )

Hydrogen applications demand stringent leak testing of the components to be tested at ultra high pressures upto 1000 / 1200 bar. The pressure needs to be ramped up in a phased manner during the leak testing process. Our Helium Leak testing machine developed for hydrogen application can be used for testing of Hydrogen components at desired set pressures.

Technical Specifications

-

Leak Detection Rate : 1 x 10 E -4 mbarl/s

-

Cycle Time : 60 Secs

-

Leak Testing Pressure : 1000 bar

-

Calibration routine : Automatic

-

Background suppression : Auto Zero

-

Helium Mixing ratio : 5%

-

Helium Recovery : > 95%

.png)